Pillow plate

What Are Pillow Plate Heat Exchangers?

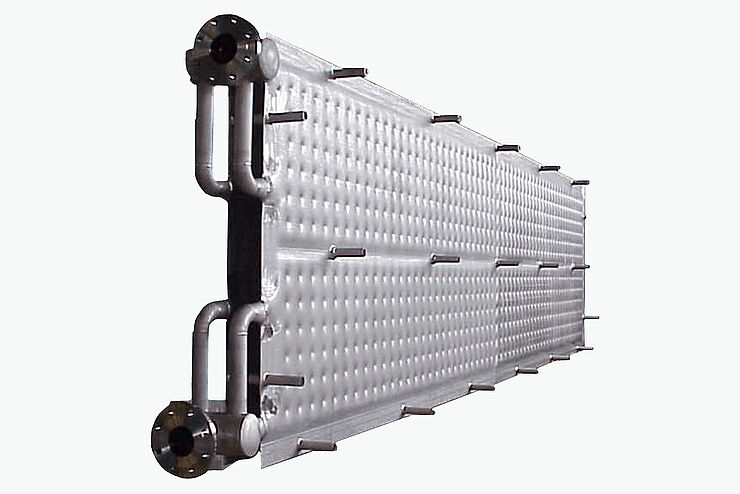

We manufacture pillow plates as single embossed pillow plate or or double embossed pillow plate that are highly flexible with their pillow plate design and can be integrated into heating and cooling applications. They are typically smaller than traditional tubular and conventional heat exchangers, depending on the distance of the weld seam and the pressure height and are innovative heat exchangers.

Pillow-plates in heat exchangers applications?

A single embossed dimple plate is typically used in process tanks, bulk or pressure vessels, cooling tables, or conveyor industries because of its flat inside surface.

On the other hand, double embossed pillow-plates can be used as pillow plate banks in any industry with alternative design that requires cooling or heating as part of their manufacturing process. It is important to note that there are two types of dimple plates: those with spot pattern and those with defined channel patterns as channels formed.

The calculation of heat exchange surfaces is specific to each fluid flow process application. One benefit of using single and double embossed pillow plate heat exchangers is that they offer flexible design options that allow for product tempering during other process steps. This eliminates the need for a separate thermal process stage and can often improve product quality. Additionally, the large heat surface of the single and double embossed dimple plate helps ensure safe process control through controlled and uniform temperature control.

What is a Pillow Plate?

A pillow plate can be either single or double welded and is created by joining two metal sheets together using either laser welding process or resistance welding process. The metal sheets may have different or the same wall thickness. A special inflation process is then used to create channels between the two heat exchange plates, which are expanded until the desired channel height is achieved. The channel height refers to the maximum distance between the metal sheets that have been welded together. The profiles and wall thicknesses of single and double embossed pillow plates with their wavy surface are chosen based on their ability to meet throughput, allowable working pressure, and pressure drop requirements.

To achieve efficient heat transfer and evenly distribute temperature inside a tank, it is advised to use a heat exchange system in the form of a double-profiled pillow plate placed directly in the tank to improve the internal surface. In tanks equipped with agitators, the double-embossed pillow plate can also function as a guiding surface for the flow, resulting in optimal mixing for homogeneous heating or cooling.

How to select Pillow Plates?

To avoid damage to the connections of the Single and double embossed pillow plates, it is necessary to lay the connecting pipe work in a way that accounts for thermal and mechanical expansion. You must also ensure that the weight of the connecting pipe work is supported by appropriate supports, and consider using expansion bends and/or joints if they are not included in the delivery scope. Finally, any connection seams that require welding must be executed and inspected following authorized procedures.

Standard connections for pillow-plates

The standard connections for a pillow plate heat exchanger can either be lateral or butt-welded. If you choose the reinforced version, the pillow plate is drilled through on the inside and the tube is welded to the plate on both sides. You can connect the fluid to pillow plates using flanges, welding nozzles, or screw pipe connections. However, it is important to note that the flow direction for the heat transfer fluid needs to be followed. For screw connections, it's important to retighten them during operation after a certain amount of time. The single or double embossed dimple plates don't require an electric connection. Despite any dirt or deposits on the plates, the U-values are only slightly affected. Using these plates results in better efficiency compared to compact external heat exchangers when there are favorable temperature differences. Additionally, products, especially food, are treated gently.

Fouling, maintenance and cleanability

Pillow plates are highly resistant to fouling and do not usually require a lot of maintenance. If deposits form on the surface, they can easily be removed by cleaning with water or detergents. Additionally, with access to both sides possible, you have the advantage of being able to clean either side without having to take apart the entire unit. The heat exchange surfaces can also be flushed in order to remove any contamination that may have formed over time. As a result, pillow plates are known for their low cost of ownership and excellent long-term performance.

The challenges of using stirring technology in agitator tanks are well-known. Typically, chemical reactions in these vessels require heat exchange surfaces to regulate product temperatures. However, the traditional method of using coils for heat exchange presents major drawbacks in terms of fouling, maintenance, and cleaning. There is a more beneficial solution in the form of star-shaped heat exchange systems with double-embossed dimple plates.

The flow breaker dimple plate system has the advantage of allowing for adjustable flow angles based on the medium being used, while also functioning as a heat exchange surface. In comparison to traditional flow breaker systems that use coils, this plate version offers benefits such as cleaner surfaces (especially with electropolished pillow plates), lower amounts of heat transfer medium required, optimized heat transfer, improved pressure drop, and the ability to adjust the mass flow angle.

High demands on surface finish

The galvanic industry requires a heat exchanger that meets specific criteria such as material durability, smooth surface finish, simple cleaning, and easy interchangeability. In temperature-controlled processes, the heat input must be uniform and gentle. As a result, systems that rely on circulating air are no longer favored. The double embossed pillow plate system can be utilized for heat exchange in various applications, such as sterilization ovens, pharmaceutical industry drying cabinets, and industrial drying ovens. It ensures uniform heat distribution and low pressure drop, thanks to its large flow cross sections.

Materials

he materials utilized in the process include stainless steel, ranging from AISI 304 to titanium. While stainless steel has low thermal conductivity, thinner walls can be designed due to its high strength and corrosion resistance. Carbon steel is often used in process fields where higher thermal conductivity is required. Moreover, prepickled, brushed, or polished metal sheets can also be utilized.

Certifications, classifications and designs

Pillow plates have undergone the necessary design, construction, and pressure testing as required for pressure equipment. As a result, they have been certified with a CE label and a declaration of conformity according to the European Pressure Equipment Directive 97/23/EC. If necessary, further certificates can be provided upon agreement.

The pressure chamber is made up of channels and fittings such as tubes with welded ends, flanges or threaded socket ends. This chamber is used to transfer heat to or from a room using a fluid. The dimple plate inside the chamber varies in volume depending on the cross-sections of the channels. More information about the design, dimensions, connections, and operational conditions can be found in the drawings or related offer. The message is written in English (United Kingdom) language code.

If the single and double embossed pi enclosing chamber are also a pressure chamber (vacuum or pressure > 0,5 bar above ambient) this has been considered in the design.

What are the advantages with Pillow-Plates?

-

Our CNC laser welding system allows for flexible geometric design parameters of pillow plates in various sizes, shapes, and materials, including both single and double embossed options.

-

By using laser welded thin sheets for the pillow plates, we keep material costs low. Single embossed plates are the one with a thinner top plate, double embossed plates have the same plate thickness.

-

These pillow shaped plates can be integrated into vessels for both mechanical and thermal purposes.

-

Additionally, their homogeneous temperature gradient ensures gentle and consistent heating or cooling of products using liquids, refrigerants, or steam in the cross sectional area.

-

Furthermore, the small inner channel volume of these dimple plates require smaller quantities of refrigerant or heating medium.

-

A thermoplate has a high heat transfer coefficient with a low pressure drop.

-

A welded pillow plate provides heat transfer, flow guidance and radiation protection across its entire surface, with a lower likelihood of fouling.

-

Pillow plates also have low inertia and better mechanical resistance to thermal cycling.

-

Their long lifetime is due to individually selected materials, and they have low production costs thanks to an automated welding process.

-

Cleaning is made easy by the accessible single or double embossed prime surface. Above all, pillow plates are reliable.

Single or double embossed pillow plate technical data

-

We offer various sizes ranging from surface area DIN A5 to 14000 x 2000 mm with a maximum operating high pressure of 50 bar.

-

The wall thickness varies between 0.8/0.8 and 3.0/3.0 mm for double embossed profiles, and up to 12 mm for single embossed profile with a rolled dimple plate.

-

We provide surfaces with different finishes such as stained, ground, and polished as per rquirement of the process industry

-

Our certificates comply with TÜV, PED, TR CU (GOST), and ASME standards.

Single or double embossed pillow plate specifications

-

We offer single and double embossed dimple plate heat exchanger that can be used with water, glycol, liquid nitrogen, thermal oil or steam with low pressure loss.

-

Additionally, we have single and double embossed dimple plate evaporators that work with all refrigerants and can be operated with a pump or injection.

Single and double embossed pillow plate applications and benefits

-

In various methods for heating and cooling liquids and foods, including using dimple jacket tank walls and pillow-plate heat exchanger manufactured by laser welding.

-

The ability to transfer heat from media with particles and various additional functions, such as flow breakers and carrier platforms.

For over 50 years BUCO single and double embossed pillow plate heat exchangers.